Production Equipment

Invested in the best technology to deliver consistent, high-quality results.

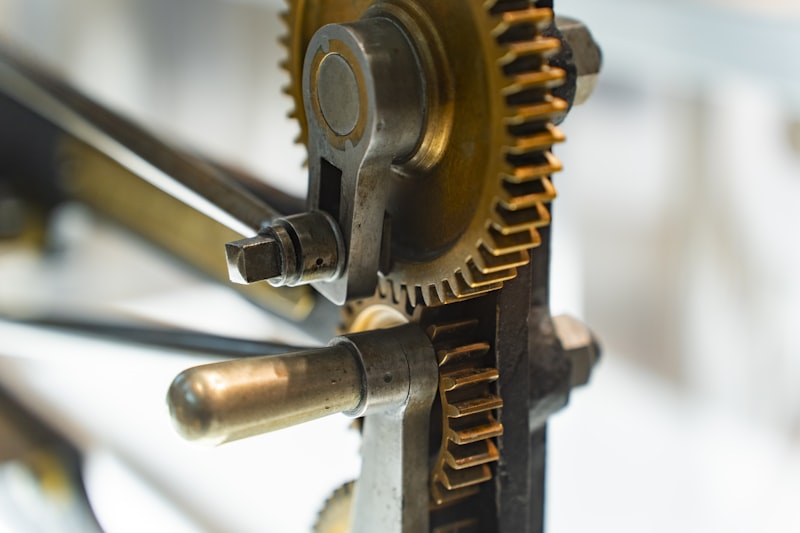

8-Color Flexographic Press

Mark Andy P7 with servo-driven registration, UV curing, and inline die-cutting. Max speed: 230m/min.

HP Indigo 6900 Digital

Full-color digital label printing with variable data, white ink, and no minimum plate charges. Ideal for short runs.

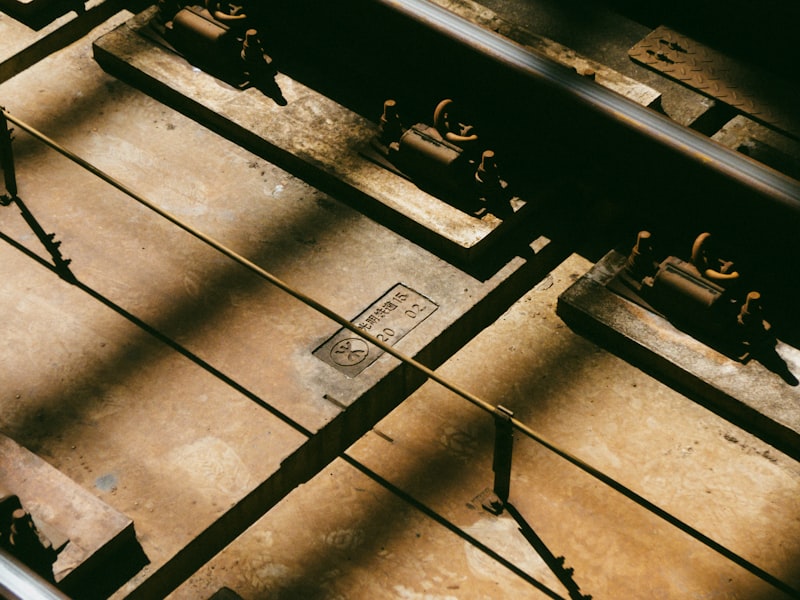

Rotary Die-Cutter

Precision ±0.1mm die-cutting with auto waste removal and multi-layer lamination capability.